Cable assemblies and wire harnesses are often referred to interchangeably because they both provide power to electrical devices. However, they are two different kinds of products.

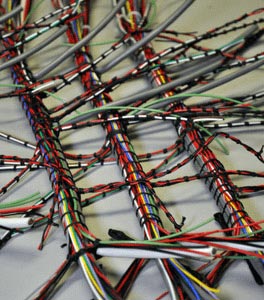

A wire harness is a bundle of wires organized together by a low-cost exterior wrap or sleeving. The wires are electrically conductive material, such as copper or aluminum. A cable assembly is a collection of cables or wires shielded by a stronger exterior material, like vinyl, thermoplastic, or thermoplastic rubber. Each cable is made up of at least two wires, which are laid out or braided together within the cable jacket.

Here you’ll learn more about wire harnesses and cable assemblies, including their respective applications.

Wire Harness vs. Cable Assembly: Similarities

Wire Harness vs. Cable Assembly: Similarities

The primary functions of both a wire harness and a cable assembly are to protect and organize wires or cables that conduct electrical currents. Both products also come protected by an insulating sleeve made of plastic or rubber, but the strength of this layer depends on whether it is a wire harness or cable assembly. In general, this layer protects the sensitive wires and cables from corrosion, shock, and impacts in their specific environments.

Wire Harness vs. Cable Assembly: Differences

Wire harnesses and cable assemblies are effective in different applications. The materials used in both products are generally the same, but the toughness of these materials differs.

Wire harnesses offer physical support for wires in protected spaces, so their insulating wrap or sleeving—usually made of PVC or plastic—provides sufficient protection for these specific environments. Unlike cable assemblies, wire harnesses are not intended for applications with extreme environmental exposure, such as dust, heat, friction, and moisture. Cable assemblies feature a durable encasement made of thermoplastic rubber, shrink-wrapped thermoplastic, or vinyl to protect electrical components from these harsh outdoor conditions. Cable assemblies are also easier to thread around tight spaces because each bundle of cables are grouped together in one sheath.

In terms of cost, wire harnesses are less expensive than cable assemblies. Wire harnesses require less material and labor to manufacture, and their cost reflects their relatively limited use cases. Cable assemblies offer a higher level of protection in a variety of harsh environments, so they are typically available at a higher price point.

Wire Harness vs. Cable Assembly: Applications

Wire harnesses are common in these industries and applications:

- Airplane engines

- Commercial and residential wiring

- Car dashboards

- Computers

- Electronics

- Garage door openers

- Soda machines

Cable assemblies are used in many industries, including:

- Military

- Aerospace

- Oil & gas electronics

- Healthcare

High-Quality Wire Harnesses and Cable Assemblies From Electro-Prep

Wire harnesses and cable assemblies both protect and organize wires that carry electrical signals. However, their differences determine the right application for each one.

Established in 1977, Electro-Prep is a turnkey contract manufacturer of custom cable assemblies, wire harnesses, box builds, and other custom electromechanical assemblies. As an ISO 9001:2015 certified company, we are committed to high quality control standards, customer satisfaction, and continuous improvement. Contact us today to learn more about our products and services, or request a quote to get your project started.