Military wire harnesses and cable assemblies are used in extreme conditions where failure is unacceptable. In these applications, rigorous regulations and quality standards must be met. Wire harnesses and cable assemblies for military-related applications are manufactured to be extremely reliable and of the highest quality.

Electro-Prep is your trusted source for custom military wire harnesses and cable assemblies. We have been manufacturing specialized products for the military for decades and produce all components according to stringent specifications.

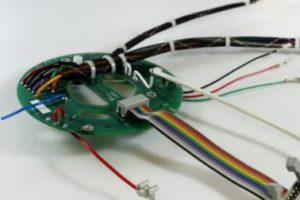

Military Wire Harnesses

Wire harnesses for military applications must meet stringent specifications and protocols as well as withstand extreme environmental operating conditions. At Electro-Prep, we design, test, and manufacture military wiring harnesses that withstand these challenges and perform reliably in intense operating theaters. Our harnesses are built to withstand conditions that include:

- High winds

- Severe vibrations

- Temperature extremes

- Water intrusion

Common applications of Electro-Prep’s military wire harnesses include:

- Military ground equipment

- Field and inter-shelter communications equipment

- Airborne communication and navigation systems

- Remote weapons control

- EMI sensitive equipment

- Avionics systems

- Space force systems

- Ships, submersibles, and other marine systems

Military Cable Assemblies

Military applications for cable assemblies involve a wide range of intense operating conditions. From extreme heat and cold to exposure to abrasive elements such as sand, dust, or corrosive seawater, military cable assemblies must be designed and manufactured to resist a broad spectrum of challenges.

Industry-related specifications are critical considerations for any cable assembly, and especially those for the military industry. Many strict government standards must be met for these applications. At Electro-Prep, our products have been selected by the military for decades for use in diverse applications that include:

- Military communications equipment

- Antenna systems

- Control panels

- Encryption systems

Electro-Prep adheres to all MIL-SPEC standards and builds products that deliver the benefits the military industry needs. Our military cable assemblies are created to feature advantages such as:

- Ruggedness: Our assemblies are built to endure the world’s harshest environments with superior operational performance.

- Reliability: Military cable assemblies from Electro-Prep are highly dependable and perform optimally – even in the types of harsh conditions that would damage other kinds of electrical equipment.

- Cost-efficient: Electro-Prep develops all custom cable assemblies with cost-effectiveness in mind.

Electro-Prep Military Wire Harness & Cable Assembly Capabilities

For decades, Electro-Prep has served the military with custom fabrication services, which include wire harnesses, cable assemblies, box builds, and electromechanical assemblies. Our industry expertise allows us to deliver high-performing solutions that meet even the most stringent military requirements.

Electro-Prep’s fabrication capabilities for military wire harnesses and cable assemblies include:

- Military wire harnesses

- Military cable assemblies

- Wire cutting services

- Wire processing services

- Wire marking services

- Wire terminations

Our custom fabrication services involve everything from a thorough design process to careful manufacturing, assembling, and testing to ensure reliable performance. Our 10,000 sq. ft. manufacturing space allows us to meet high-volume orders with minimal lead times.

With years of contract manufacturing experience and a thorough understanding of military specifications, Electro-Prep is a trusted provider of top-quality military products. We provide wire harnesses and cable assemblies for all types of military systems and devices, including PackBot robots, surveillance systems, unmanned underwater vehicles, and more.

Electro-Prep is in full compliance with:

- J-STD soldering standards

- IPC-620 workmanship standards

- 9001:2015 certification

- ITAR registered

Electro-Prep: Your Source for Dependable Solutions

For more than 40 years, Electro-Prep has crafted custom wire harnesses and cable assemblies that meet the most demanding requirements. Our military wire harnesses and cable assemblies meet all industry-related specifications and are built to perform in the world’s most challenging environments. Whatever your wire harness or cable assembly needs, we have the technical expertise and military industry experience to deliver the quality products you need.

You can learn more about Electro-Prep’s solutions for the military by contacting us today. If you have a wire harness or cable assembly application you’d like to discuss with our team, please request a quote.