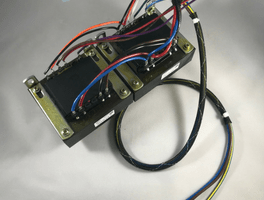

Similar to our growth into electro mechanical assemblies, custom assembly and/or integration grew out of customer requests.

Existing box-build, wire and cable customers asked if we could again extend our manufacturing capabilities so they could take advantage of our quality, service, and customer-oriented mindset. A number of customers now rely on Electro-Prep to build the final products they design and market to their customers. Is product assembly one of your core competencies? As your volumes fluctuate wildly, what assembly work would you rather pass off to a highly capable outside supplier who you trust?

- You design it (sometimes, with a little help from Electro-Prep), provide a print, sketch, or even sample with bill of materials, and we’ll build it

- Wire, cable, electronic components or not

- Prompt turn-around of prototype and/or pre-production assemblies

- Fast production ramp-up on both small and larger runs

All of our custom assembly and integration is built in-house by our experienced and expertly trained personnel to assure that our customers receive the highest quality products. Our certified, on-site trainers make sure all product lives up to our ISO 9001:2015 certification, along with our IPC-620 workmanship standards and J-STD soldering standards. Our state-of-the-art, expertly maintained equipment, including Schleuniger, Cirrus, Tyco, and Molex machines, provides another major advantage.

To learn more about our custom assembly and integration, request a quote today.