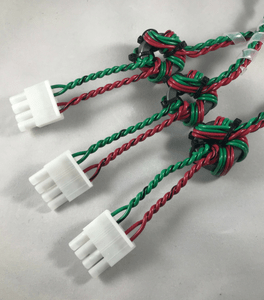

Electro-Prep’s products are beautifully crafted to meet your requirements.

We work with discrete wire from 4/0 to 32-gauge, multi-conductor cable from 2 to over 100 conductors, and cut it to virtually any length and reasonable tolerance. Choose from some of the more common wire and cable options below or select something more appropriate for your designs. Alternatives include:

- Discrete PVC-insulated wire

- Teflon-insulated wire

- Multi-conductor round cable

- Flat ribbon cable

- Coaxial cable

- Numerous other variations and options

Wire and Cable Preparation gets most of our work started.

Our operations to complete your design may include:

- Cutting

- Stripping

- Window Stripping

- Jacket Stripping

- End-Preparation

- Tinning

- Soldering

- Splicing

- Marking

- Terminating

- Feed Through Tubing or Sleeving

- Pull-Testing

- Twisting

- Plugging In

- Taping

- Epoxy Application

- Cable-Tie

- Bread-Tie

- Heat-Shrink Tubing

- Labeling

- Coiling

- Cirrus Testing

- Bagging

- Packaging

All of our wire and cable preparation is done in-house by our experienced and expertly trained personnel to assure that our customers receive the highest quality products. Our certified, on-site trainers make sure all product lives up to our ISO 9001:2015 certification, along with our IPC-620 workmanship and J-STD soldering standards.

We employ state-of-the-art equipment including:

- Schleuniger computer-controlled cut and strip machines to cut your wire and cable

- Cirrus automated test systems to confirm the accuracy of our work

- Various semi-automatic machine TE, Molex, G-Press, K-Press