Case Studies

Leave a CommentAs a trusted provider of custom wire and cable assemblies, Electro-Prep delivers comprehensive solutions for demanding industries. Our services provide benefits such as improved design for manufacturability, reduced lead times, and products that meet rigorous testing and quality standards. These case studies outline solutions Electro-Prep has provided for customers in several diverse industries.

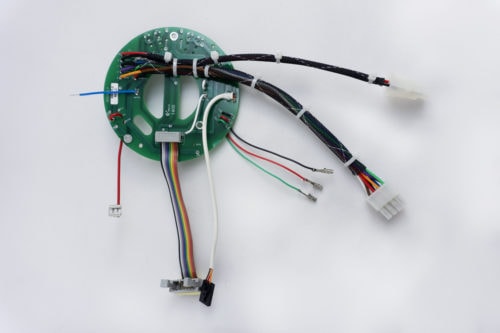

Custom Printed Circuit Board (PCB) Wire Harness (Spider Board) for a Military Application

In addition to wire harnesses and subassemblies, Electro-Prep, Inc. is also a trusted provider of “spider board assemblies” to a DOD contractor. As the primary assembly provider for the entire PCBA assembly, we deliver high standards and unmatched service. In this case study, Electro-Prep designed and now constructs 11 different wire harness assemblies for a military application.

In addition to wire harnesses and subassemblies, Electro-Prep, Inc. is also a trusted provider of “spider board assemblies” to a DOD contractor. As the primary assembly provider for the entire PCBA assembly, we deliver high standards and unmatched service. In this case study, Electro-Prep designed and now constructs 11 different wire harness assemblies for a military application.

The customer supplies us with printed circuit boards and we then make all the solder connections as well as perform all of the final assembly work for all 11 wire harnesses. During this process we:

- Use a wide array of terminal types as well as rectangular connectors to build a variety of wire harness assemblies

- Lay out the wiring and make both soldered and crimped terminations

- Make SMD connections using precision fine-tip soldering techniques and then protect the wire from wear damage by using nylon sleeving.

Each board undergoes visual inspection and full electrical testing before it is shipped to the customer. Wire harness assemblies from Electro-Prep are built to IPC-620 workmanship standards as well as J-STD soldering standards and can be supplied in medium to high volume quantities.

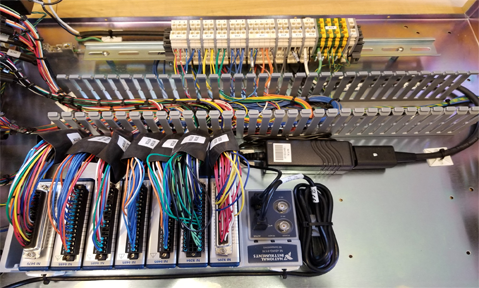

Custom Manufactured Electromechanical Assembled Box-Build (Junction Box) for Water Purification Industry

Electro-Prep supplies junction boxes for a multinational company in the water purification industry. This company originally approached us for a turnkey electromechanical assembly solution. We worked closely with them to engineer an electromechanical box-build that met budget and quality criteria.

Electro-Prep supplies junction boxes for a multinational company in the water purification industry. This company originally approached us for a turnkey electromechanical assembly solution. We worked closely with them to engineer an electromechanical box-build that met budget and quality criteria.

Electro-Prep created a design that featured pressure-rated watertight housing. However, after it was determined that creating this custom item would extend beyond the company’s budget, we quickly began investigating acceptable alternatives. Within a few days, we located a standard housing that, with minor modifications, would meet cost and design objectives.

The finalized electromechanical assembly consists of watertight housing, custom gaskets, cable glands, and DIN rail terminal blocks. Electro-Prep developed custom tooling that optimizes the speed and accuracy of the assembly process and guarantees timely product delivery. Our quality assurance analytics ensure UL standards, as well as the client’s specified pressure tolerances, are met.

Custom Wire Harness for Marine Industry

Electro-Prep improved product production and assembly time for a marine industry manufacturer that produces a wide array of unmanned underwater vehicles (UUVs). We developed a solution for binding and combining wires into a single harness, streamlining the vehicle’s wiring process while complying with industry performance and safety standards.

Electro-Prep improved product production and assembly time for a marine industry manufacturer that produces a wide array of unmanned underwater vehicles (UUVs). We developed a solution for binding and combining wires into a single harness, streamlining the vehicle’s wiring process while complying with industry performance and safety standards.

Throughout this process we:

- Designed and fabricated a subsea qualified wire harness using forming boards.

- Created a design with manufacturability in mind, ensuring the highest possible degree of repeatability in the final product.

- Employed semi-automatic and hand crimping tools to minimize production time.

- Built custom-engineered fixtures to perform 100% continuity testing.

This harness combines multi-conductor cable with discrete wires, rectangular connectors, splicing, and soldiered terminations. We also use military wire lacing as it is the easiest for the company’s assemblers to work with when installing the harness in tight locations.

Case Studies from Electro-Prep

Electro-Prep provides custom-engineered solutions that help take businesses to the next level. For more information on our capabilities and services, contact us today or request a quote to get started.

Electromechanical Assemblies 101

Leave a CommentChoosing the right electromechanical assembly manufacturer is critical to the success of your program and associated projects. The right business partner can accommodate your design needs, deliver assemblies on time and within budget, and provide reliable support for every stage of the project. To ensure your assembly is built to the highest standards, your manufacturer will need the following information:

- Bill of materials (BOM)

- Drawings

- Schematics

- Wire run lists

- Testing protocols

- Sample units

With this information, your preferred manufacturer can verify if they have the right capabilities and availability to manage your project successfully.

What Is An Electromechanical Assembly?

Electromechanical assemblies are often found in electrical and electronic systems and consist of a variety of electromechanical components and subassemblies that perform a wide range of functions. Mechanical assembly is the process of incorporating these components and subassemblies into a cohesive system that can produce more advanced functionality.

One of the most common types of electromechanical assemblies is a box build. Box builds or system integrations can be simple or complex and implement a box or other similar enclosure to house the components of the assembly. The manufacturer will often route the cables and wires from the enclosure to their intended destination, creating a compact, efficient solution.

Manufacturers use specialized tools and equipment to produce assemblies at scale, and different service providers will offer different manufacturing and assembly capabilities.

Benefits of Electromechanical Assemblies

Choosing the right manufacturer for electromechanical assemblies can optimize your business processes and streamline the production of new products. Some of the benefits of choosing Electro-Prep for manufacturing electromechanical assemblies include:

- Complete Engineering and Design Support: Along with managing the physical construction of electromechanical assemblies, our engineering teams can support design processes, testing, and design improvement processes. This allows for more efficient production of superior products, as we can streamline the design to fit cost-effective manufacturing processes with the fewest steps necessary.

- Detailed Document Control: We are a professional electromechanical assembly manufacturer with turnkey solutions and can assist with complete document control. Through the use of enhanced engineering software, we can provide important documentation, including bills of material, prototyping and testing documentation, as well as clear product specifications.

- Engineering and Manufacturing to Cost: By working with a single service provider, companies can simplify logistics and reduce costs, both for themselves and their intended target market while producing a higher quality product.

- Prototyping: Many complex electromechanical assemblies need to undergo multiple virtual or physical revisions to optimize the design for functionality and production. Our team can ensure your products are safe, compliant with applicable standards and regulations, and constructed with the optimal materials and configurations through prototyping before production begins.

Components and Sub-Assemblies in Electromechanical Assemblies

Electromechanical assemblies often include the following components:

- Custom Wire Harnesses and Cable Assemblies: Custom wiring assemblies disperse electrical currents to the correct parts and subassemblies in the system. We design them to be rated to perform based on your assembly’s specifications and to extend the lifespan of the product.

- DIN Rails: Mounting rails in box-builds can streamline assembly by simplifying mounting and ensuring fragile components have enough space and stability.

- Pneumatics: Complex assemblies may have pneumatic sub-assemblies and components such as valves, pistons, air regulators, and more.

- Power Supplies: Power supplies convert the voltage, current, and frequency of electricity from a power source to fit the needs of the assembly.

- Printed Circuit Boards (PCBs): PCBs are a modern alternative to wire circuit boards. They are more compact, efficient, and durable.

- Programmable Logic Controllers (PLCs): PLCs are the control units that manage the functions of sub-assemblies within the assembly. They gather and compute data to initiate outputs based on previously determined parameters.

- Relays: These components open and close circuits based on output commands from the assembly’s PLC.

- Safety Components: Assemblies require safety components like sensors, breakers, and switches that mitigate the risk of equipment damage and injuries to users.

Electromechanical Assemblies From Electro-Prep

At Electro-Prep, we specialize in providing turnkey electromechanical assembly services. To learn more about our capabilities, download our eBook, “The Ultimate Guide To Electro-Mechanical Assemblies & Box-Builds.” For over 40 years, our engineering teams have designed, manufactured, and assembled complex assemblies. Contact us today to learn more about our capabilities or request a quote to get your project started.

Box-Build Assembly Process: A Quick Guide

Leave a CommentBox-builds refer to the combination of subassemblies and/or electro-mechanical components within a panel or enclosure. Depending on the specifications of your particular application, box-builds can either be a simple installation of a single PCB in a small enclosure or a highly complex and intricate installation of numerous components and subassemblies into large panels.

Box-Build Assembly Process

While box-builds can vary significantly based on the components involved and the complexity of the final product, most processes follow the same basic steps. These steps are:

While box-builds can vary significantly based on the components involved and the complexity of the final product, most processes follow the same basic steps. These steps are:

- Project Preparation. Before the project can begin, your box-build manufacturer needs documentation to ensure they can fully meet the needs of the project. This documentation includes design files, a bill of materials (BOM), schematics, testing data, and more. The more complete the documentation from the start, the better the service provider can gauge their ability to manage the assembly project and lower the risk of error.

- Testing the Components. The individual electrical components and sub-assemblies will be tested to ensure they each perform according to their specifications prior to installation.

- Preparing the Wires and Cables. Box-build manufacturers will cut, strip, crimp, and label the wires and cable assemblies prior to configuring them within the enclosure.

- Assembly. Box-build manufacturers will install and connect all of the components and wiring within the box from the bottom up.

- Labeling and Testing/Inspecting. At this stage, the builders label the individual components and sub-assemblies and test/inspect the entire assembly at defined intervals.

- Software Installation. Complex electronic assemblies also have software to make the assembly function. Box-builders will install the software and test it.

Typical Components and Sub-Assemblies in Box-Builds

Simple and complex box-builds can incorporate a wide range of components, subassemblies, and hardware. The most common elements in a box-build include:

- Cable Assemblies

- Custom Wire Harnesses

- DIN Rails

- Pneumatic Systems

- Power Supplies

- Printed Circuit Boards (PCBs)

- Relays

- Safety Components

- Programmable Logic Controllers (PLCs)

Benefits of Partnering With a Box-Build Expert

Partnering with the right box-build expert can streamline your production and ensure a higher degree of product quality and longer-lasting assemblies. Some of the benefits of partnering with an experienced expert in the industry include:

- Increasing Cost-Effectiveness and Adhering to Budget Constraints. Box-build experts can optimize the production process to guarantee that your product has the most cost-effective and efficient design. Working with one vendor also helps to reduce lead time and streamline assembly operations.

- Streamlining the Production Process. Partnering with a box-build expert eliminates the need to maintain communication with multiple suppliers and manage the production process. This allows you to focus your energy on other important business areas where you’re the experts.

- Increasing Product and Process Quality. Box-build experts have the tools, resources, and supply partners to ensure optimal product consistency and high-quality box-build solutions.

- Reduced Risk of Costly Miscommunication. If you work with multiple suppliers at once, you automatically have a higher risk for miscommunication and errors. Partnering with a box-build expert eliminates this risk, ensuring your product is delivered as you intended.

Box-Build Assemblies From Electro-Prep

At Electro-Prep, we have a long history as a leading service provider in the box-build industry. Our employees are certified to meet IPC-620A (IPC/WHMA-A-620) and J-STD-001 standards, and our company is ISO 9001:2015 certified. We’re committed to providing high-quality services during every stage of production and assembly to ensure your product meets your every need. Contact us today to learn more about our box-build capabilities, or request a quote to get your project started.