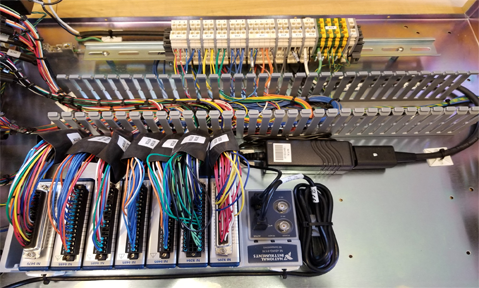

Box-builds refer to the combination of subassemblies and/or electro-mechanical components within a panel or enclosure. Depending on the specifications of your particular application, box-builds can either be a simple installation of a single PCB in a small enclosure or a highly complex and intricate installation of numerous components and subassemblies into large panels.

Box-Build Assembly Process

While box-builds can vary significantly based on the components involved and the complexity of the final product, most processes follow the same basic steps. These steps are:

While box-builds can vary significantly based on the components involved and the complexity of the final product, most processes follow the same basic steps. These steps are:

- Project Preparation. Before the project can begin, your box-build manufacturer needs documentation to ensure they can fully meet the needs of the project. This documentation includes design files, a bill of materials (BOM), schematics, testing data, and more. The more complete the documentation from the start, the better the service provider can gauge their ability to manage the assembly project and lower the risk of error.

- Testing the Components. The individual electrical components and sub-assemblies will be tested to ensure they each perform according to their specifications prior to installation.

- Preparing the Wires and Cables. Box-build manufacturers will cut, strip, crimp, and label the wires and cable assemblies prior to configuring them within the enclosure.

- Assembly. Box-build manufacturers will install and connect all of the components and wiring within the box from the bottom up.

- Labeling and Testing/Inspecting. At this stage, the builders label the individual components and sub-assemblies and test/inspect the entire assembly at defined intervals.

- Software Installation. Complex electronic assemblies also have software to make the assembly function. Box-builders will install the software and test it.

Typical Components and Sub-Assemblies in Box-Builds

Simple and complex box-builds can incorporate a wide range of components, subassemblies, and hardware. The most common elements in a box-build include:

- Cable Assemblies

- Custom Wire Harnesses

- DIN Rails

- Pneumatic Systems

- Power Supplies

- Printed Circuit Boards (PCBs)

- Relays

- Safety Components

- Programmable Logic Controllers (PLCs)

Benefits of Partnering With a Box-Build Expert

Partnering with the right box-build expert can streamline your production and ensure a higher degree of product quality and longer-lasting assemblies. Some of the benefits of partnering with an experienced expert in the industry include:

- Increasing Cost-Effectiveness and Adhering to Budget Constraints. Box-build experts can optimize the production process to guarantee that your product has the most cost-effective and efficient design. Working with one vendor also helps to reduce lead time and streamline assembly operations.

- Streamlining the Production Process. Partnering with a box-build expert eliminates the need to maintain communication with multiple suppliers and manage the production process. This allows you to focus your energy on other important business areas where you’re the experts.

- Increasing Product and Process Quality. Box-build experts have the tools, resources, and supply partners to ensure optimal product consistency and high-quality box-build solutions.

- Reduced Risk of Costly Miscommunication. If you work with multiple suppliers at once, you automatically have a higher risk for miscommunication and errors. Partnering with a box-build expert eliminates this risk, ensuring your product is delivered as you intended.

Box-Build Assemblies From Electro-Prep

At Electro-Prep, we have a long history as a leading service provider in the box-build industry. Our employees are certified to meet IPC-620A (IPC/WHMA-A-620) and J-STD-001 standards, and our company is ISO 9001:2015 certified. We’re committed to providing high-quality services during every stage of production and assembly to ensure your product meets your every need. Contact us today to learn more about our box-build capabilities, or request a quote to get your project started.