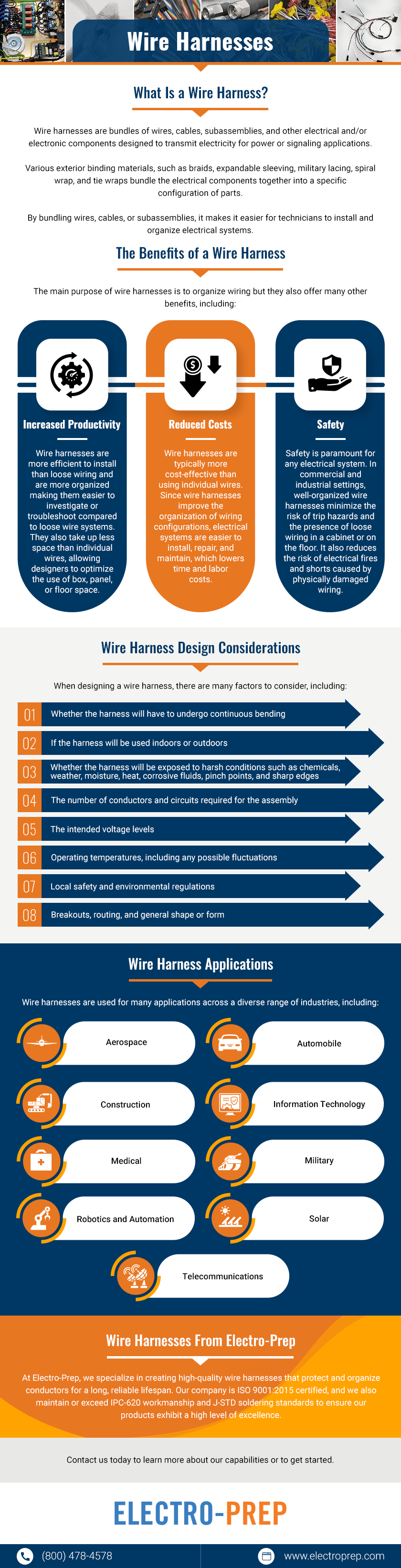

Wire harnesses are used in many industries to organize and streamline wiring systems. These versatile, multi-wire bundles can be assembled in various ways to suit different industrial, commercial, and consumer applications in both indoor and outdoor environments.

What Is a Wire Harness?

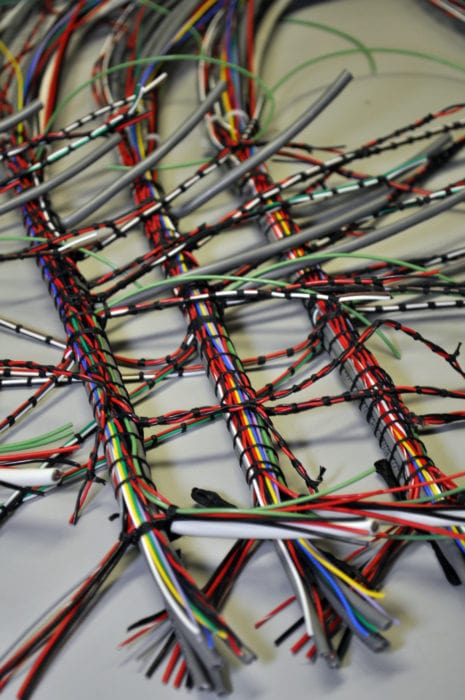

Wire harnesses are bundles of wires, cables, subassemblies, and other electrical components designed to transmit electricity for power or signaling applications. Various exterior binding materials, such as braids, expandable sleeving, military lacing, spinal wrap, and tie wraps bundle the electrical components together into a specific configuration of parts. By bundling wires, cables, or subassemblies, it makes it easier for technicians to install and organize electrical systems.

Wire harnesses are often confused with cable assemblies. Cable assemblies are single units containing multiple conductors within a single jacket, while wire harnesses consist of multiple jacketed wires that are bundled together.

The Benefits of a Wire Harness

The main purpose of wire harnesses is to organize wiring but they also offer many other benefits, including:

Increased Productivity

Wire harnesses are more efficient to install than loose wiring and are more organized making them easier to investigate or troubleshoot compared to loose wire systems. They also take up less space than individual wires, allowing designers to optimize the use of box, panel, or floor space.

Reduced Costs

Wire harnesses are typically more cost-effective than using individual wires. The assemblies protect conductors from abrasion, pinching, moisture, tears, and vibration, thereby minimizing the risk of damage and reducing material expenses. Since wire harnesses improve the organization of wiring configurations, electrical systems are easier to install, repair, and maintain, which lowers time and labor costs.

Safety

Safety is paramount for any electrical system. In commercial and industrial settings, well-organized wire harnesses minimize the risk of trip hazards and the presence of loose wiring in a cabinet or on the floor. This protects employees from physical injury and reduces company liability. It also reduces the risk of electrical fires and shorts caused by physically damaged wiring.

Wire Harness Design Considerations

Wire harnesses are designed to reduce assembly costs by simplifying wire installation. When designing a wire harness, there are many factors to consider, including:

Wire harnesses are designed to reduce assembly costs by simplifying wire installation. When designing a wire harness, there are many factors to consider, including:

- Whether the harness will have to undergo continuous bending

- If the harness will be used indoors or outdoors

- Whether the harness will be exposed to harsh conditions such as chemicals, weather, moisture, heat, corrosive fluids, pinch points, and sharp edges

- The number of conductors and circuits required for the assembly

- The intended voltage levels

- Operating temperatures, including any possible fluctuations

- Local safety and environmental regulations

- Breakouts, routing, and general shape or form

Considering these factors during the design process ensures that the final product is efficiently built and serves its purpose.

Wire Harness Applications

Wire harnesses are used for many applications across a diverse range of industries, including:

- Aerospace. Wire harnesses are used to transmit power and communication signals to and within aircrafts, drones, and satellites.

- Automobile. Wire harnesses allow automobile manufacturers to efficiently use the space in the dashboard, under the hood, and inside doors. Technicians can also diagnose problems or make modifications more easily.

- Construction. Wire harnesses are used within buildings and structures to protect and organize wiring systems.

- Information Technology. Servers and other IT equipment, such as computers and laptops, use wire harnesses to organize a multitude of wires.

- Medical. Wire harnesses organize wires between and inside medical equipment to reduce malfunctions and trip hazards, especially on mobile equipment.

- Military. Wire harnesses are used in military-grade batteries, vehicle lighting, and more.

- Robotics and Automation. Wire harnesses group and protect wires in robotic systems.

- Solar. Solar cell energy systems use wire harnesses to transmit energy and send signals. Their wire harnesses are specially built to withstand heat, high voltage levels, the elements, and UV radiation.

- Telecommunications. Common equipment such as modems, repeaters, and routers use wire harnesses to organize and route wiring.

Wire Harnesses From Electro-Prep

At Electro-Prep, we specialize in creating high-quality wire harnesses that protect and organize conductors for a long, reliable lifespan. Our company is ISO 9001:2015 certified, and we also maintain or exceed IPC-620 workmanship and J-STD soldering standards to ensure our products exhibit a high level of excellence. Contact us today to learn more about our capabilities or to get started.