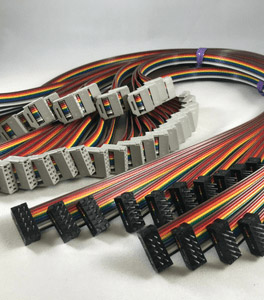

Electro-Prep is a leading provider of high-quality, custom wire and cable solutions. One of our core product offerings is ribbon cable assemblies. They are available in a variety of pitches and conductor counts to match any standard insulation displacement connectors (IDC) and in various materials to withstand high temperatures and other harsh environmental conditions.

Electro-Prep is a leading provider of high-quality, custom wire and cable solutions. One of our core product offerings is ribbon cable assemblies. They are available in a variety of pitches and conductor counts to match any standard insulation displacement connectors (IDC) and in various materials to withstand high temperatures and other harsh environmental conditions.

What Are Ribbon Cables?

Ribbon cables—also known as flat ribbon cables or planar cables—are characterized by their flat, rectangular shape that resembles a piece of ribbon. They consist of wires running parallel to one another on the flat plane, which creates a wide and flat cable.

The unique design of ribbon cable assemblies makes them ideal for use in straight-run applications involving confined or limited spaces. Typical uses include data transmission and communication systems as well as computer components (e.g., hard drives, CD drives, and floppy drives). They can also be utilized as internal wiring for various appliances, electronics, testing and measuring instruments, and robotics.

Types of Ribbon Cables and Connectors

Ribbon cables are available in many variations, each of which is suitable for different applications. The most common types include:

- Standard ribbon cables. In addition to its compact design, a standard ribbon cable is highly valued for its mass termination capabilities. This quality helps reduce the amount of labor required for assembly and, consequently, the overall cost of assembly.

- Rainbow ribbon cables. Rainbow ribbon cables are similar to standard ribbon cables. However, the wires have different colors to facilitate organization and identification. Additionally, in some cases, the ends are split to allow for individual termination.

- Twisted flat ribbon cables. Twisted ribbon cables are also similar to standard ribbon cables but have pairs of wires that are twisted and bonded together. They have alternating parallel and twisted wire sections. The twisted pairs reduce the risk of cross talk, while the parallel pairs ensure the connectors and PCB headers can be terminated with traditional IDC ribbon cabling methods.

- Round-to-flat ribbon cables. Round-to-flat ribbon cables begin with a circular bundle of wires that splits apart for individual use. They are perfect for use in tight spaces.

- Bonded ribbon cables. Bonded ribbon cables are designed to keep wires organized from end to end. While the bonding process removes some of the assembly’s flexibility, it makes mass termination much easier.

The connector designations commonly used for ribbon cables are:

- BT224

- D-subminiature

- Micro ribbon

- DIN 41612

- PCB transition header

- DIL headers

Advantages of Ribbon Cables

There are many advantages to using ribbon cables. The main advantage is their ease of termination and customizability. They can be mass terminated to specifically designed IDC connectors or terminated by crimp contacts or solder-cup connectors. Additionally, they can be designed and constructed in a variety of configurations to suit different applications.

Partner With Electro-Prep for Your Ribbon Cable Needs Today

Looking for high-quality, low-cost ribbon cables for your electronic application? Turn to the wire and cable experts at Electro-Prep!

Looking for high-quality, low-cost ribbon cables for your electronic application? Turn to the wire and cable experts at Electro-Prep!

Our highly experienced and fully trained employees carefully design and build our custom wire and cable products to ensure they meet your product specifications and our strict standards. By maintaining on-site training, we ensure all wire and cable solutions live up to our ISO 9001:2015 certification and our IPC-620 workmanship and J-STD soldering standards.

Our custom ribbon cable capabilities include:

- 2 to 100 conductors in wide-spacing to high-density configurations

- IDC, MDR, and many other connector options

- Integration with other electronic components and materials

- Ability to perform 100% electrical continuity testing with Cirrus test systems

- Flat flexible cable (FFC) alternatives

To learn more about our ribbon cable capabilities, contact us today. To discuss your requirements with one of our team members, request a quote.