At Electro-Prep, our core competency has always been building wire harnesses and cable assemblies. Throughout the years, as more and more customers recognized the superiority of our products, services, and customer-oriented mindset, they asked us to expand our manufacturing capabilities to encompass complete part and product assemblies. Today, box-builds and electro-mechanical assemblies are an important part of our business, as many of our customers rely on us to bring their designs to life.

At Electro-Prep, our core competency has always been building wire harnesses and cable assemblies. Throughout the years, as more and more customers recognized the superiority of our products, services, and customer-oriented mindset, they asked us to expand our manufacturing capabilities to encompass complete part and product assemblies. Today, box-builds and electro-mechanical assemblies are an important part of our business, as many of our customers rely on us to bring their designs to life.

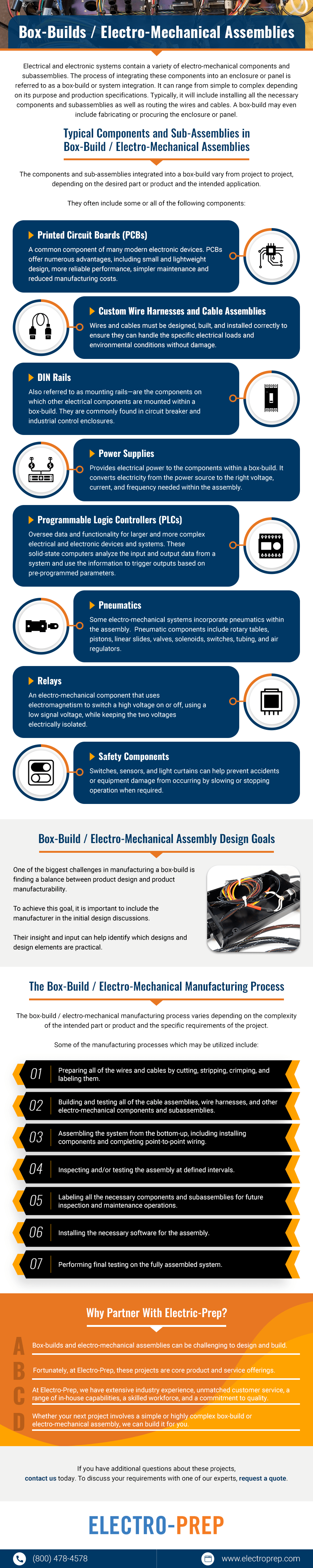

Electrical and electronic systems contain a variety of electro-mechanical components and subassemblies. The process of integrating these components into an enclosure or panel is referred to as a box-build or system integration. It can range from simple to complex depending on its purpose and production specifications. Typically, it will include installing all the necessary components and subassemblies as well as routing the wires and cables. A box-build may even include fabricating or procuring the enclosure or panel.

Interested in learning more about box-builds and electro-mechanical assemblies? Below, we discuss the typical components and sub-assemblies found in box-builds and electro-mechanical assemblies, the primary goal in designing them, and the steps taken to produce them.

Typical Components and Sub-Assemblies in Box-Builds/Electro-Mechanical Assemblies

The components and sub-assemblies integrated into a box-build vary from project to project, depending on the desired part or product and the intended application. They often include some or all of the following components:

Printed Circuit Boards (PCBs)

Printed circuit boards (PCBs) are a common component of many modern electronic devices. Compared to traditional wire circuits, they offer numerous advantages, including small and lightweight design, more reliable performance, simpler maintenance and reduced manufacturing costs. They can range from simple one- or two-layer boards for devices like a television remote to 60-layer boards and higher for complex systems like a high-end server or supercomputer.

Custom Wire Harnesses and Cable Assemblies

The wires and cables within a box-build ensure that electrical transmissions are directed to the correct components and sub-assemblies. To accomplish this, those wires and cables must be designed, built, and installed correctly to ensure they can handle the specific electrical loads and environmental conditions without damage. The experts at Electro-Prep can help design and then manufacture custom wire and cable assemblies for virtually any project. Our product specialties include radio-frequency (RF) and coaxial cable assemblies, ethernet cable assemblies, power cables assemblies, and flat and ribbon cable assemblies utilizing insulation displacement connectors.

DIN Rails

DIN rails—also referred to as mounting rails—are the components on which other electrical components are mounted within a box-build. They are commonly found in circuit breaker and industrial control enclosures.

Power Supplies

The power supply provides electrical power to the components within a box-build. It converts electricity from the power source (such as an outlet, generator, or battery) to the right voltage, current, and frequency needed within the assembly.

Programmable Logic Controllers (PLCs)

Programmable logic controllers (PLCs) oversee data and functionality for larger and more complex electrical and electronic devices and systems. These solid-state computers analyze the input and output data from a system and use the information to trigger outputs based on pre-programmed parameters.

Pneumatics

Some electro-mechanical systems incorporate pneumatics within the assembly. Pneumatic components such as rotary tables, pistons, and linear slides are used to convert air pressure to linear or rotational movement. Other pneumatic components can include valves, solenoids, switches, tubing, and air regulators. The experts at Electro-Prep provide manual assembly and installation assistance for a variety of pneumatic components within a box-build or electro-mechanical assembly.

Relays

A relay is an electro-mechanical component that uses electromagnetism to switch a high voltage on or off, using a low signal voltage, while keeping the two voltages electrically isolated. Relays can also be used in combination with one another to perform Boolean logic functions. Time-delay relays are available that only allow systems to start or stop after a specified time.

Safety Components

Safety should be an important consideration when designing and building any box-build assembly. Safety components, such as switches, sensors, and light curtains can help prevent accidents or equipment damage from occurring by slowing or stopping operation when required.

Box-Build/Electro-Mechanical Assembly Design Goals

One of the biggest challenges in manufacturing a box-build is finding a balance between product design and product manufacturability. While certain designs may function within the required specification, they may not be easy to manufacture. This can lead to higher product assembly costs and poor quality. Conversely, the designs may be easy to manufacture, but the desired functional and aesthetic goals are not met. In the best-case scenario, the box-build design should contain all of the desired elements while being feasible and affordable to manufacture. Achieving this goal necessitates including the manufacturer into initial design discussions. Their insight and input can help identify which designs and design elements are practical.

One of the biggest challenges in manufacturing a box-build is finding a balance between product design and product manufacturability. While certain designs may function within the required specification, they may not be easy to manufacture. This can lead to higher product assembly costs and poor quality. Conversely, the designs may be easy to manufacture, but the desired functional and aesthetic goals are not met. In the best-case scenario, the box-build design should contain all of the desired elements while being feasible and affordable to manufacture. Achieving this goal necessitates including the manufacturer into initial design discussions. Their insight and input can help identify which designs and design elements are practical.

Box-Build/Electro-Mechanical Manufacturing Process

The box-build / electro-mechanical manufacturing process varies depending on the complexity of the intended part or product and the specific requirements of the project. Some of the manufacturing processes which may be utilized include:

- Preparing all of the wires and cables by cutting, stripping, crimping, and labeling them

- Building and testing all of the cable assemblies, wire harnesses, and other electro-mechanical components and subassemblies

- Assembling the system from the bottom-up, including installing components and completing point-to-point wiring

- Inspecting and/or testing the assembly at defined intervals

- Labeling all the necessary components and subassemblies for future inspection and maintenance operations

- Installing the necessary software for the assembly

- Performing final testing on the fully assembled system

Prior to performing any of the above steps, box-build / electro-mechanical assembly manufacturers must acquire certain pieces of information to ensure they build the assembly correctly. The most important pieces of information are the bill of materials (BOM), drawings, and schematics. Additional documents, including wire run lists, test protocols, and sample units, help ensure creating a quality product.

Why Partner With Electro-Prep?

Box-builds and electro-mechanical assemblies can be challenging to design and build. Fortunately, at Electro-Prep, these projects are core product and service offerings. By partnering with us for your box-build / electro-mechanical assembly needs, you benefit from our:

- Extensive industry experience. We have provided high-quality products to our customers for over 40 years. This experience enables us to answer and address any questions or issues you may have.

- Unmatched customer service. We are committed to meet your needs because we believe when you succeed, we succeed.

- Commitment to quality. We maintain ISO 9001:2015 certification and a dedication to providing quality products and services.

- Broad range of in-house capabilities. In addition to our system integration capabilities, we provide in-house design and build services for custom wire harnesses and cable assemblies.

- Highly skilled workforce. All of our employees are certified to IPC-620A (IPC/WHMA-A-620) workmanship and J-STD-001 soldering standards. We also maintain a certified trainer on staff.

Whether your next project involves a simple or highly complex box-build or electro-mechanical assembly, we can build it for you. If you have additional questions about these projects, contact us today. To discuss your requirements with one of our experts, request a quote.